Product List

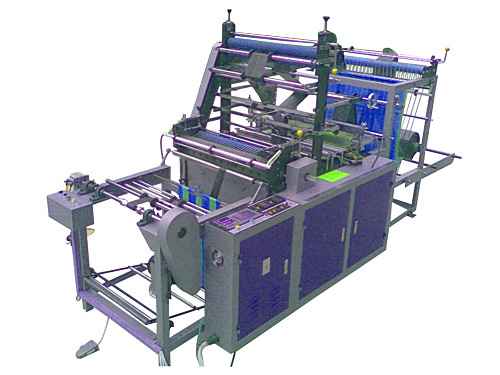

Garbage bag bag making machine

Product details

The machine is suitable for the plastic bags break point of rewinding operation. To adopt the automatic control into, and silicon controlled control device, give into accurate and correct; The single step double transmission match with thirty percent edge device makes the film width and much smaller, high superior integrated electronic plug-in circuit system control photoelectric sensor, high precision, long life, easy maintenance; Photoelectric sensor can control the color printing bag, guarantee and printing design synchronous, control printing film bag length, length is in 500 mm below, the error in within 1 mm; The variable frequency speed can accurately adjust speed bags, plastic film into uniform to guarantee. Equipped with heat welding knife to be automatic from film institutions, when when stop heat welding knife to be automatic raise from film, in order to avoid the film long heated and fusing; The digital temperature control meter automatic temperature control, high precision; The pressure adjusting mechanism, can according to the different thickness, adjust the pressured the film solder strength; Some cutting knife using high strength high speed steel paper made from durable; The winding device adopts stepless speed regulation make the receiving flat compact. Has the feeding, welding, point to break, count, the winding, quote-automation control function, nissan can reach 8-120000 only. This machine automation degree and production efficiency reached domestic products advanced level.

|

Model |

JBE-700 |

JBE-900 |

|

Bag making length |

200-700mm |

200-800mm |

|

Bag making width |

150-350mm |

150-500mm |

|

Film thickness |

0.01-0.06mm |

0.01-0.06mm |

|

Production capacity |

20-140( minutes ) |

20-140( minutes ) |

|

The main motor |

0.75kw |

0.75kw |

|

Material feeding motor |

200w |

200w |

|

Rewinder motor |

300w |

300w |

|

Heating power |

1.5 kw×2 |

1.5 kw×2 |

|

Envelop dimensions high aspect ratio |

4000×1300×1600mm |

4000×1500×1600mm |

|

Net weight |

800? |

900? |